|

Hubei Boyuejia Industrial Co., Ltd.

|

Gold Index: 8312

Exterior ceramic 600x600 Flexible Wall Tiles waterproof for Decoration

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

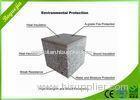

Exterior flexible ceramic wall tile waterproof simizu wall tile long duration

<b

Exterior flexible ceramic wall tile waterproof simizu wall tile long duration

1. Specification:

|

Tile type |

Flexible Wall Tiles |

|

Size |

600mm*600mm |

|

Thickness |

2mm~3mm |

|

Composition |

plasticizer, clay and mineral powder, quartz sand etc, |

|

Color |

We can produce all kinds of color according to your requirement |

|

Usage |

Interior and Exterior wall decoration |

|

Packaging: |

Standard cartons |

|

Delivery time |

Within 15 days after received the payment |

|

Payment terms |

TT, L/C |

|

Supply ability |

50000square meters per month |

|

Remark |

All kind of designs can be produced according to your requirements |

2. Technical Index:

|

Test Item |

Technical Index |

Test Method |

|

|

Appearance |

At least 95% area, without visible defect |

GB/T3810.2-2006 |

|

|

Surface Density(kg/m2) |

8 |

GB/T4100-2006 |

|

|

Moisture Rate (kg/m3h0.5) |

<0.1 according to Europe Standard |

EN1062-3:2008 |

|

|

Ventilation Property, Vapor flow density g/(m3h) |

0.85 |

GB/T17146-1997 |

|

|

Age Resistance |

3500h, without crackle in appearance, sparging and pulverization is less than 1 level |

GB/T1865-1997 |

|

|

Frost Resistance |

After 100times recycled use, without crackle, spalling, pulverization in visible |

GB/T3810.12-2006 |

|

|

Stain Resistance |

Grain side products=4 level, regular roughness products=3 level, no requirement on sand finish and irregular products. |

GT/T3810.14-2006 |

|

|

Dimension Stability |

±0.5% |

HG/T3747.1-2004 |

|

|

Tensile-Strength |

1.0Mpa |

GB/T528-2009 |

|

|

Combustibility |

Thickness >3mm, A level, Thickness3mm according to requirements on tactile impression painting |

GB/8624-2006 |

|

|

Alkali Stability |

No dilapidation, spalling, like stone |

GB/T3810.13-2006 |

|

|

Acid Resistance |

48h no abnormalities |

DBJ50-046-2006 |

|

|

Harmful substance limit |

Dissoluble Lead |

20 |

HJ/T297-2006 |

|

Dissoluble Cadmium |

5 |

||

|

TVOC(mg/kg) cancerogen |

0.5 |

GB/T18587-2001 |

|

|

Radioactivity |

IRA |

0.9 |

GB6566 |

3. Installation Process:

1. Spread Tile Adhesive mixture to the tiles

Snap the line, and stick cement adhesive mixture to back side of the tiles. Adhesive mixture should be evenly applied and the thickness should be 2-3 mm, and adhesive area should cover more than 85%.

2. Fill the joints

The joints should be filled by special cement-based gap filler or silicone adhesive meeting National Standard. The adhesive mixture is not allowed to fill the joints directly to avoid alkali efflorescence.

3. Point Joints

The joints should be made by copper rod, and the joints should be dished, smooth, plump.

4. Clean wall tiles

Clean the dirt of joint filler or cement mortar on surface and sides of the tiles before setting, mapping by dry sponge or scratching by plaster trowel. Fabric cloth with water is not allowed, or else resulting in alkali efflorescence.

5. Process Exterior Corners

1) Hitom edge is on the left side of the interface, with a smooth seam sealant.

2) Make 45°Diagonal by rotary sander, and match two tiles correctly.

3) Lapping joints is not allowed at exterior joints when tiles are thin. For lapping joints, 2-3 mm seam should be made at the lapping. The seam should be filled by joint fillers and someone must be put in charge of the work, then painted by coating of same color.

4. Reference

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Hubei Boyuejia Industrial Co., Ltd. [China (Mainland)]

Business Type:Manufacturer

City: Wuhan

Province/State: Hubei

Country/Region: China (Mainland)