|

Hubei Boyuejia Industrial Co., Ltd.

|

Gold Index: 8312

Waterproof Concrete Prefab House Made By EPS Cement Sandwich Panels

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

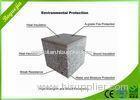

Waterproof Concrete Prefab House Made By EPS Cement Sandwich Panels

<

Waterproof Concrete Prefab House Made By EPS Cement Sandwich Panels

Description:

1. Different thickness lightweight EPS sandwich panels for interior/exterior wall

2. Roof: lightweight eps cement panel or color steel sandwich panel

3. Aluminum alloy window can bring you the economical and practical.

4. Doors: according to your requirement

5. Installation Materials: cement adhesive, Putty Powder, PU foam, PU foam shooting Gun, anti-crack

tape, wall tile for exterior wall etc.

Sizes of EPS cement sandwich panel:

|

Length (mm) |

Width (mm) |

Thickness (mm) |

Density (kg/m2) |

Application |

Appearance |

|

2270

2440

3000 |

610 |

50 |

38±5 |

Non-load bearing wall of houses and buildings |

With calcium silicate board as face board, solid |

|

60 |

42±5 |

||||

|

75 |

45±5 |

||||

|

90 |

52±5 |

||||

|

100 |

56±5 |

||||

|

120 |

62±5 |

||||

|

150 |

72±5 |

||||

|

180 |

85±5 |

||||

|

200 |

95±5 |

Other points:

1. The columns are inside the sandwich panel which makes it more beautiful and reality.

2. Compared with the earth building, the price is much lower and the installation time is much shorter.

3. Fire rate partition: 4 hours under 1000 degrees, reach to A level

4. Sound insulation: 38-46db

5. Thermal Conductivity: 0.221w/mk

6. Anti-earthquake: depend on the strength of steel structure (8 grade)

7. The using life is around 40-70 years.Environmental protection and economy.

8. Each worker can assemble 30~40 square meters/day on average, easy and fast installation.

9. Loading: 100square meters can be loaded in one 40 feet shipping container.

Installation Steps:

1. Setting the line

2. carrying the board into position

3. Using a hand-hold electric saw to the sizes needed

4. Sizing cement on tenon side of two boards, then spread polymer mortar on one tenon side casually

5. Carrying the board prepared to be installed to the installation place, correcting the wall board by

special tools, and making it close tightly, and let the polymer mortar squeeze out into full and then fixing

it with a wedge temporarily

6. Planting bars in wall and pillar: drill a hole in the original pillar or wall, and fix the board by steel bars

7. Correcting and fixing: Using a guiding rule to check the vertical and leveling correction.

8. Planting bars between two boards, plant a steel bar in the angle of 45 degree to fix

9. Installing electrical wires and switches: setting lines on the places needing to be set with concealed

wire and switch box

10. Grouting and filling starch: filling and sticking the corrected wall board with polymer mortar

11.After the polymer and wall are all shaped, sticking glass-cloth or anti-cracking tape, brushing coating.

Product Image:

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Hubei Boyuejia Industrial Co., Ltd. [China (Mainland)]

Business Type:Manufacturer

City: Wuhan

Province/State: Hubei

Country/Region: China (Mainland)