|

Hubei Boyuejia Industrial Co., Ltd.

|

Gold Index: 8312

High Temperature Resistance Soft Split Face Tiles 2-4mm Thickness

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Soft Split Face Brick Interior Wall Decoration High Temperature Resistance 2-4mm Thickness <span style="font-size:14px"

Soft Split Face Brick Interior Wall Decoration High Temperature Resistance 2-4mm Thickness

Description

Compared with the exteriror dry hanging of the marble, granite, the construct of Split Face Brick is more light weight, which greatly save the construction period, we used origin and natureal raw material for the texture, basic on the traditional and modern art processing, colletc more than 300 kinds of color tone, and elegant, abundant innate color, timeless, non-distortion, non-color changes within 30 years, which apply to the modern ruban architecture characteristics of return to nature.

Specification

Tile type | Split Face Brick |

Size | 300mm *300mm, 300mm *600mm, 600mm*600mm |

Thickness | 2mm~3mm |

Composition | plasticizer, clay and mineral powder, quartz sand etc, |

Color | We can produce all kinds of color according to your requirement |

Usage | Interior and Exterior wall decoration |

Packaging: | Standard cartons |

Delivery time | Within 15 days after received the payment |

Payment terms | TT, L/C |

Supply ability | 100,000spuare meters per month |

Remark | All kind of designs can be produced according to your requirements |

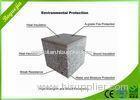

| Lightweight, anti-seismic, high security |

| Flame-retardant, smokeless, excellent fireproof performance |

| Superior chemical stability, makes products get self-cleaning, and get longer acid resistance, durability, weatherability |

Energy-saving and low-carbon, eco-friendly and healthy, suitable for both inside and outside decoration |

| Potential energy-saving space, thickness is about one-third of brick wall |

| Excellent flexibility, super peel strength and impact resistance |

| Intelligent breathable, antibacterial and antifungal, mouldproof, waterproof, excellent crack resistance |

| High bonding strength |

| Simple construction, color diversity reveal natural effect |

Technical Index

Breathability, Wet Steam Flow Density g/(m2h) | ≥0.85 |

Frost-Resistance | After 100 cycles,no surface crack, flake by naked eye observation |

Ageing Resistance | 3500h, no cracking, gas robe phenomenon pulverization is less than level 1 |

Combustion Performance | More than 3mm thickness A Level Less than 3mm,according to the requirements of Texture coating |

Tensile Strength | ≥1.0MPa |

Dimensional Stability | ±0.5% |

Stain Resistance | Smooth product = 4 level; concave and convex surface products=3 level |

Alkali Resistance | 800h, No blisters, peeling phenomenon, just like stone |

Acid Resistance 2%,H | 48h, Normal |

Soluble lead | ≤20 |

Soluble cadmium | ≤5 |

TV((mg/kg)(cancerogen) | ≤0.5 |

Usage

1) All kinds of new and old building constructions of indoor and outdoor decoration;

2)Indoor and outdoor decoration of office buildings, hospitals, shops, restaurants, bars and other pu -blic buildings;

3) Interior and exterior wall decoration of family homes, luxury apartments, villas etc;

4) Particularly suitable for high-rise building exterior wall insulation decoration.

Installation

1.Spread Tile Adhesive mixture to the tiles

Snap the line, and stick cement adhesive mixture to back side of the tiles. Adhesive mixture should be evenly applied and the thickness should be 2-3 mm, and adhesive area should cover more than 85%.

2. Fill the joints

The joints should be filled by special cement-based gap filler or silicone adhesive meeting National Standard. The adhesive mixture is not allowed to fill the joints directly to avoid alkali efflorescence.

3. Point Joints

The joints should be made by copper rod, and the joints should be dished, smooth, plump.

4. Clean wall tiles

Clean the dirt of joint filler or cement mortar on surface and sides of the tiles before setting, mapping by dry sponge or scratching by plaster trowel. Fabric cloth with water is not allowed, or else resulting in alkali efflorescence.

5.Process Exterior Corners

1)Hitom edge is on the left side of the interface, with a smooth seam sealant.

2)Make 45°Diagonal by rotary sander, and match two tiles correctly.

3) Lapping joints is not allowed at exterior joints when tiles are thin. For lapping joints, 2-3 mm seam should be made at the lapping. The seam should be filled by joint fillers and someone must be put in charge of the work, then painted by coating of same color.

Split Face Brick

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Hubei Boyuejia Industrial Co., Ltd. [China (Mainland)]

Business Type:Manufacturer

City: Wuhan

Province/State: Hubei

Country/Region: China (Mainland)