|

Hubei Boyuejia Industrial Co., Ltd.

|

Gold Index: 8312

Partition wall EPS Cement Insulated Concrete Sandwich Panels Fast Installation

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Fast Installation Precast Concrete Sandwich Panels For Partition Panels

Fast Installation Precast Concrete Sandwich Panels For Partition Panels

Description:

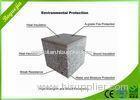

EPS & Cement Sandwich Panel is a kind of lightweight energy saving wall material, which uses cement calcium silicate or reinforced calcium silicate board as face panel, filled with cement, EPS polystyrene foam particles, and as core material and forming by one time compound.

1) Composition: calcium silicate board as face panel on both sides, cement and EPS polystyrene form as core.

2) Usage: This EPS cement sandwich panel can be widely applied to all kinds of decoration and building construction, they are the best materials for plants, apartments, hotels, office buildings and public constructions, etc. In addition, they are used for compartments, households, bathrooms, the interior partition walls of kitchens in the high-rise building and housing renovation projects.

3) Loading Quantity:

| Name | Size(mm) | Weight(Kg) | Packing(pcs/m2/20'GP) |

| Precast Concrete Sandwich Panel | 2270*610*60 | 45-48 | 315pcs/436m2 |

| 2270*610*75 | 50-53 | 252pcs/349m2 | |

| 2270*610*90 | 55-58 | 207pcs/287m2 | |

| 2270*610*100 | 60-65 | 189pcs/262m2 | |

| 2270*610*120 | 65-75 | 153pcs/212m2 | |

| 2270*610*150 | 80-90 | 126pcs/175m2 | |

| 2270*610*180 | 95-105 |

99pcs/138m2 |

Specifications:

|

Product Name |

Specification(mm) |

Weight(kg/m2) |

Allowed Tolerance(mm) |

|

Precast Concrete Sandwich Panels |

2270*610*60 |

45~48 |

Length±5 Width±2 Thickness±1 Diagonal±2

|

|

2270*610*75 |

50~53 |

||

|

2270*610*90 |

55~58 |

||

|

2210*610*100 |

60~65 |

||

|

2210*610*120 |

65~75 |

||

|

2210*610*150 |

80~90 |

||

|

2210*610*180 |

95~105 |

Installation Process:

| 1) Setting the line and carrying the board into position | Eject double lines of board thickness up and down the axes of installed wall board, and easily carry to the side of wall according to the specification needed; |

| 2) Sawing board | Using a hand-hold electric saw freely according to the specification of wall, which can reduce the loss rate; |

| 3) Sizing | Sizing the bump slots and then spread the baseline and the bump slots with the Boyuejia special adhesives; |

| 4) Installation | Carrying the board prepared to be installed to the installation place, correcting the wall board by gavelock and making it close tightly, and let the polymer mortar squeeze out into full and fixing it with a chock temporarily; |

| 5) Correcting and fixing | Using the guiding rule of two meters to check the verticality and leveling correction. Then using 6mm or 8mm reinforcing steel bar and ribs adding with construction sealant to fix; |

| 6) Grouting and filing starch | Using BOYUEJIA speicial adhesives to fill the gaps between the corrected wall boards after one day later. Then putting the chock out and letting the corrected wall smoothly with polymer mortar; |

| 7) Grooving and piping | Cutting a groove by hand-hold electric saw for buring the concealed wire and switch box, then filling with polymer mortar after installation; |

| 8) Sticking anti-cracking tape | After grouting 3-5 days later, st

Related Search

Insulated Sandwich Panels

Eps Sandwich

Sandwich Panels

Eps Sandwich Panel

Eps Roof Sandwich Panel

Eps Sandwich Machinery

More>>

Find more related products in following catalogs on Hisupplier.com

Company InfoHubei Boyuejia Industrial Co., Ltd. [China (Mainland)]

Business Type:Manufacturer You May Like:

Printable Page

Bookmark this page

Sitemap XML About HiSupplier Help Center Customer Service Friend Links Site Map Archives Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español Copyright © HiSupplier.com Online Inc. All Rights Reserved.

|